Introduction to Electrical Transformers

What is an Electrical Transformer?

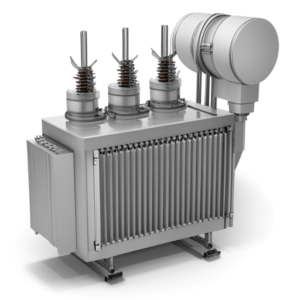

An electrical transformer is a static device that transfers electrical energy from one circuit to another through electromagnetic induction. It consists of two or more windings, usually made of copper wire, which are wound around a magnetic core.

Importance of Electrical Transformers in Power Systems

Electrical transformers play a vital role in power systems by enabling voltage transformation, distribution, and regulation. They facilitate the efficient transmission of electricity from power generation sources to end-users, ensuring the reliable operation of electrical equipment and systems.

Types of Electrical Transformers

Step-Up Transformers

Step-up transformers increase the voltage from the input (primary) side to the output (secondary) side. They are commonly used in power transmission systems to step up voltage levels for long-distance transmission with reduced energy losses.

Step-Down Transformers

Step-down transformers decrease the voltage from the input (primary) side to the output (secondary) side. They are widely utilized in power distribution networks to step down high-voltage electricity from transmission lines to lower voltage levels suitable for consumer use.

Distribution Transformers

Distribution transformers are designed for use in distribution networks, where they step down voltage levels from transmission lines to levels suitable for residential, commercial, and industrial consumers. They are typically mounted on utility poles or installed in substations.

Power Transformers

Power transformers are large-scale transformers used in high-power applications, such as power generation plants and substations. They are capable of handling high voltages and currents, making them suitable for transferring bulk electrical power over long distances.

Isolation Transformers

Isolation transformers provide electrical isolation between the input and output sides, preventing direct electrical connection and reducing the risk of electrical shock. They are commonly used in sensitive electronic equipment and medical devices.

Auto Transformers

Autotransformers have a single winding shared between the primary and secondary circuits, allowing for voltage transformation with a smaller footprint compared to conventional transformers. They are often used in applications where space is limited.

Components of Electrical Transformers

Core

The core of an electrical transformer provides a path for the magnetic flux generated by the windings. It is typically made of high-permeability materials such as silicon steel or ferrite.

Windings

The windings are conductive coils of wire wound around the core of the transformer. They serve as the primary and secondary circuits of the transformer, facilitating the transfer of electrical energy through electromagnetic induction.

Tapping Points

Tapping points are intermediate connections along the winding of a transformer that allows for adjustable voltage output. They provide flexibility in voltage regulation and adaptation to varying load conditions.

Terminals

Terminals are the connection points on the transformer where external conductors are attached. They provide a means for connecting the transformer to the primary and secondary circuits of the electrical system.

Cooling Mechanisms

Cooling mechanisms such as fans, radiators, or oil-filled tanks are used to dissipate heat generated during transformer operation. They help maintain optimal operating temperatures and prevent overheating of the transformer components.

Working Principle of Electrical Transformers

Faraday’s Law of Electromagnetic Induction

Faraday’s law states that a change in magnetic flux through a conductor induces an electromotive force (EMF) or voltage in the conductor. This principle forms the basis of electromagnetic induction in transformers.

Mutual Induction in Transformers

Mutual induction occurs when a changing magnetic field produced by one winding induces a voltage in another winding. This phenomenon allows for the transfer of electrical energy between the primary and secondary circuits of a transformer.

Voltage Transformation Ratio

The voltage transformation ratio of a transformer is the ratio of the output voltage to the input voltage. It determines the extent of voltage transformation achieved by the transformer and is typically expressed as a numerical ratio.

Operation Modes: Step-Up and Step-Down

Transformers can operate in step-up mode, where the output voltage is higher than the input voltage, or step-down mode, where the output voltage is lower than the input voltage. The mode of operation depends on the configuration of the transformer windings.

Applications of Electrical Transformers

Power Distribution

Electrical transformers are essential for distributing electrical power from generation sources to end-users through transmission and distribution networks. They ensure efficient energy transfer and voltage regulation across the grid.

Voltage Regulation

Voltage regulation is crucial for maintaining a stable power supply and protecting electrical equipment from voltage fluctuations. Electrical transformers regulate voltage levels, ensuring consistent and reliable operation of electrical systems.

Motor Starting

Electrical transformers provide voltage boost during motor starting to overcome initial inertia and facilitate smooth operation. They are essential for starting heavy-duty motors in industrial machinery and equipment.

Equipment Operation

Electrical transformers power various electrical equipment, including pumps, compressors, HVAC systems, and lighting fixtures, enabling their efficient and reliable operation in industrial settings.

Transformer Rectifier Units (TRUs)

Transformer rectifier units (TRUs) convert alternating current (AC) to direct current (DC) for powering electrochemical processes, such as electrolysis and electroplating, in industrial applications.

Key Considerations for Transformer Selection

Voltage Rating

The voltage rating of a transformer must match the voltage requirements of the electrical system it serves. It determines the maximum voltage that the transformer can withstand without insulation breakdown.

Current Capacity

The current capacity of a transformer, often expressed in terms of kilovolt-amperes (kVA) or amperes (A), determines the maximum load it can handle without overheating or exceeding its design limitations.

Efficiency

Transformer efficiency refers to the ratio of output power to input power, expressed as a percentage. Higher-efficiency transformers minimize energy losses and reduce operating costs over the lifespan of the transformer.

Size and Weight

The size and weight of a transformer impact its installation, transportation, and space requirements. Compact and lightweight transformers are preferred for applications where space is limited or mobility is essential.

Environmental Conditions

The operating environment, including temperature, humidity, altitude, and exposure to contaminants, influences the performance and lifespan of a transformer. Transformers designed for specific environmental conditions ensure reliable operation and longevity.

Maintenance and Troubleshooting

Regular Inspection and Testing

Regular inspection and testing of transformers are essential for identifying potential issues and ensuring optimal performance. Visual inspections, electrical tests, and diagnostic techniques are used to assess transformer health.

Oil Analysis

Oil analysis is a common technique used to monitor the condition of transformer insulation and cooling systems. It involves analyzing the chemical composition and physical properties of transformer oil to detect signs of degradation or contamination.

Temperature Monitoring

Temperature monitoring helps prevent overheating and insulation breakdown in transformers. Sensors and monitoring devices are used to measure transformer temperatures and trigger alarms or protective actions when temperatures exceed safe limits.

Cleaning and Lubrication

Cleaning and lubrication of transformer components, such as terminals, cooling fans, and bushings, help maintain optimal performance and prevent corrosion or mechanical failures. Regular maintenance tasks include dusting, wiping, and applying lubricants as needed.

Troubleshooting Common Issues

Troubleshooting common transformer issues, such as overheating, insulation failure, and voltage regulation problems, requires systematic diagnostic procedures and corrective actions. Timely identification and resolution of issues prevent downtime and costly repairs.

Conclusion

Electrical transformers are essential assets in modern power systems, enabling voltage transformation, power distribution, and equipment operation across various applications. Understanding their types, components, working principles, applications, and maintenance requirements is crucial for optimizing transformer performance, ensuring reliable operation, and minimizing downtime in electrical systems.

FAQs of Electrical Transformer

1. What is the purpose of an electrical transformer?

Answer: The primary purpose of an electrical transformer is to transfer electrical energy from one circuit to another through electromagnetic induction. It is commonly used to step up or step down voltage levels for power distribution, voltage regulation, and equipment operation in electrical systems.

2. What are the main components of an electrical transformer?

Answer: The main components of an electrical transformer include the core, windings, tapping points, terminals, and cooling mechanisms. The core provides a path for magnetic flux, while the windings are conductive coils that facilitate energy transfer. Tapping points allow for adjustable voltage output, and terminals provide connection points for external conductors. Cooling mechanisms help dissipate heat generated during transformer operation.

3. What are the different types of electrical transformers?

Answer: There are several types of electrical transformers, including step-up transformers, step-down transformers, distribution transformers, power transformers, isolation transformers, and auto transformers. Each type has specific applications and operating characteristics suited to different voltage transformation requirements.

4. How does an electrical transformer work?

Answer: An electrical transformer works on the principle of electromagnetic induction, where a changing magnetic field induces a voltage in a nearby conductor. When an alternating current (AC) flows through the primary winding of a transformer, it generates a changing magnetic field in the core, which, in turn, induces a voltage in the secondary winding, resulting in electrical energy transfer between the primary and secondary circuits.

5. What are some common maintenance tasks for electrical transformers?

Answer: Common maintenance tasks for electrical transformers include regular inspection and testing, oil analysis, temperature monitoring, cleaning, and lubrication. Visual inspections, electrical tests, and diagnostic techniques are used to assess transformer health, while oil analysis helps monitor insulation conditions. Temperature monitoring helps prevent overheating, and cleaning and lubrication maintain optimal performance and prevent mechanical failures.

These FAQs provide valuable insights into the purpose, components, types, working principle, and maintenance of electrical transformers, helping users understand their importance and functionality in electrical systems.